Please click here to access the main AHDB website and other sectors.

- Home

- Knowledge library

- Downy mildew control in protected crops of cut flower column stocks

Downy mildew control in protected crops of cut flower column stocks

Here we review the key factors in protected column stock disease management following the emeregence of metalaxyl resistant strains of downy mildew in 2018 covering trials carried out from 2018-2023.

Grower summary

- Downy mildew diseases are best managed via a combination of cultural and chemical control measures within an integrated crop management programme

- Cultural control measures include adequate structure ventilation, use of trickle irrigation and application of appropriate levels of crop nutrients

- Growers should obtain fungicide application records from their plug plant suppliers and take these into account when creating crop fungicide programmes

- Select fungicide products with an appropriate mode of action to achieve the desired effect, taking into account stage of crop growth, disease development and application method

- Programmes based on protectant fungicides must be implemented three to five days after planting and before the onset of any visible disease symptoms

- Fungicides from at least three different fungicide groups, as specified by the Fungicide Resistance Action Committee (FRAC), should be used in any programme

- Products from different groups can be used in tank mixes (where manufacturers permit this), or alternated within spray programmes

- Spray intervals should be reduced; for example, from 14 to seven days when environmental conditions favour downy mildew; and less than seven days when the temperature is between 15°C and 21°C and the relative humidity is above 70%, or during long periods of leaf wetness

- Spray applications must achieve good coverage of leaves throughout the crop canopy

- Where rapid vegetative growth occurs in the early stages of the crop while overhead irrigated, the intervals between spray applications should be shorter, especially under favourable environmental conditions, to protect new growth

- Minimise the application of solid formulation fungicides at the point of flowering to reduce the risk of potential leaf deposits on cut flower stems at marketing

c/o Lyndon Mason

c/o Lyndon Mason

Background

Column stocks are a significant non-bulb, protected cut flower crop grown in the UK. Around 15 million stems were produced during 2018. Under conducive weather conditions, column stocks can be susceptible to downy mildew caused by the pathogen Peronospora parasitica. The pathogen was traditionally prevented or managed by adopting a regular spray programme based on specific fungicides, including products containing the active ingredient metalaxyl-M. However, during the early part of 2018, crops grown in the Netherlands reportedly suffered from a very severe infection of downy mildew that did not respond to standard fungicide spray programmes. By mid-May, UK crops were also beginning to suffer from this disease. Despite using the usual range of fungicides, growers found that the pathogen caused severe damage, with infections appearing almost overnight. Even a reduction in the spray interval did not appear to achieve the necessary level of control and work was urgently needed to evaluate the pathogen for its sensitivity to different fungicide active ingredients.

Disease development and symptoms

P.parasitica is an oomycete, a fungus-like organism that develops internally within the host plant. The pathogen only becomes visible at sporulation, for which high humidity is required. The optimum temperature for infection and sporulation is between 15°C and 21°C, at this temperature, infection can take place in as little as four hours of leaf wetness. Under optimum conditions, the latent period between infection and symptom development can be as little as five to six days.

It is worth noting that, although spore germination is low at 21°C, the degree of sporulation and percentage level of infection are still high. This suggests the pathogen is very aggressive under late spring and early autumn conditions, when the temperatures are sufficient and the relative humidity in glasshouse structures is still high. It is important to note that sporulation will start in temperatures as low as 4.5°C and will stop completely at 27°C.

The first indications of disease are the appearance of light green areas on the upper leaf surface. On the lower surface, corresponding to these areas, a white sporulation can be seen. The infected areas increase in size and coalesce, very often covering the entire leaf lower surface. Infected areas turn yellow and become necrotic, with infected leaves falling prematurely. The flowers of infected plants frequently fail to open and often die. The disease is most destructive when plants are infected at the seedling stage.

c/o Lyndon Mason

c/o Lyndon Mason

Typical symptoms and pathogen sporulation from an infection of Peronospora parasitica

Sensitivity and phytotoxicity testing

In agreement with industry, sensitivity testing of downy mildew isolates taken from stocks in commercial production against a range of fungicide products started in 2018 and continued to 2023.

Pathogen samples were taken from infected plant material from nurseries in different geographical locations including Northern Ireland, Cornwall, Norfolk and Lincolnshire. The samples were submitted to FERA, where staff inoculated column stock seedlings to permit the pathogen to establish, develop and build up (the pathogen is an obligate parasite and cannot be cultured in vitro). Testing used the spores generated to inoculate trial plants. These trials assessed industry pathogen samples for fungicide sensitivity whilst also allowing for horizon scanning of new fungicide products with potential for securing new approvals on the most promising products.

The replicated trials were undertaken on small plants grown in 9 cm containers in a glasshouse structure using either a testing knapsack sprayer in 2018 and a track-sprayer in subsequent years.

All of the pathogen samples obtained had low sensitivity to the active ingredient metalaxyl-M (Subdue) even in last trial in 2023 when the virulence of the pathogen was thought to be declining. It was assumed that the mancozeb element within Fubol Gold WG gave this product the recorded level of disease control. Dimethomorph (Paraat and as a mixture in Percos) and mandipropamid (Revus) gave the best levels of control from the approved options in both 2018 trials.

Signum and Stroby WG were included in the 2018 trials as a negative control as it is known these two products do not have activity against downy mildew which effectively validated the trial.

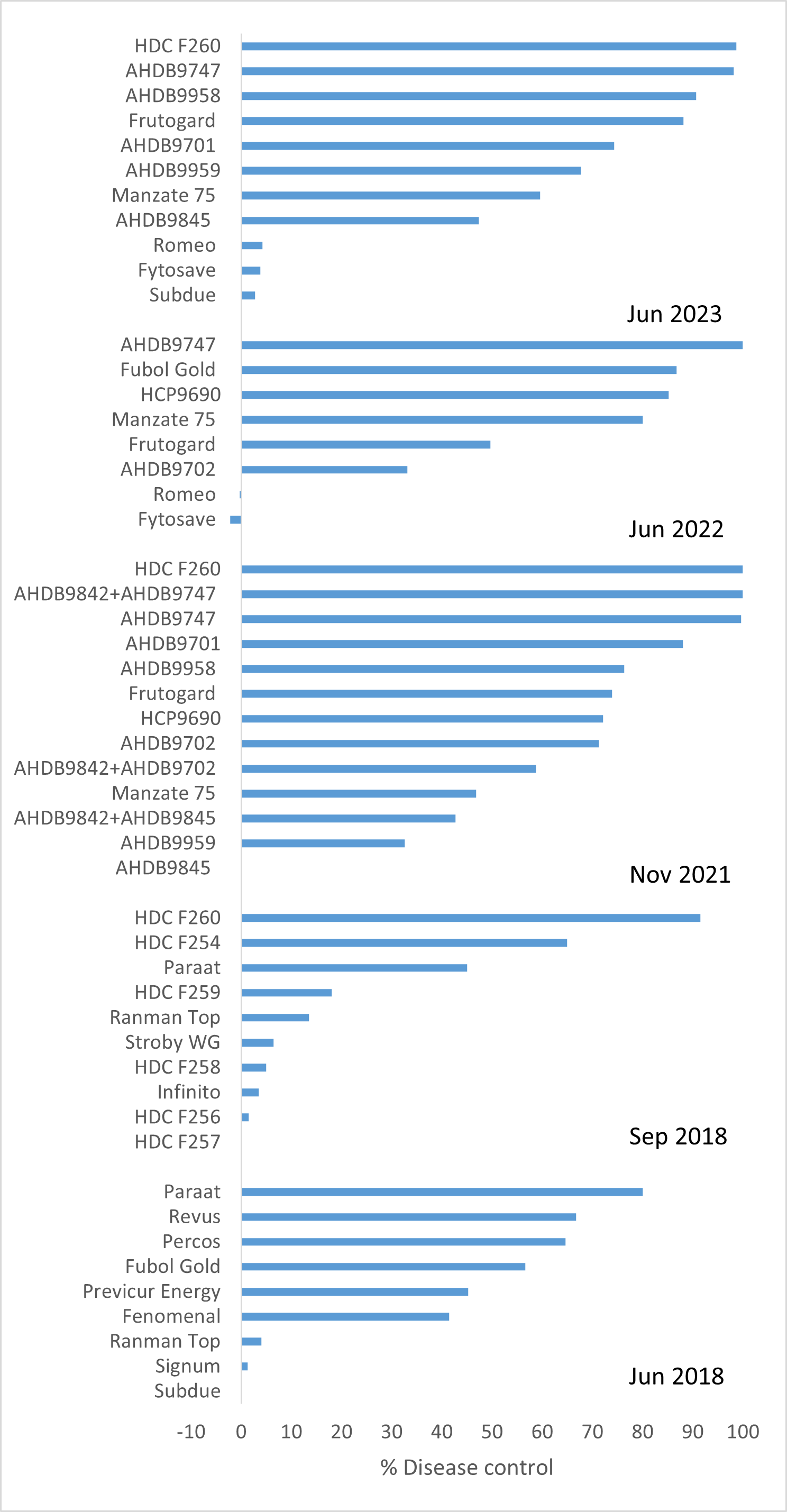

Across all years of testing two products HDCF260 and AHDB9747 gave consistently the best results with control over 90% in all trials where included. The second group of products AHDB9701, HCP9690, Frutogard, AHDB9958 largely gave over 70% control in the years where these were included. To date Frutogard has been progressed for EAMU, whilst the other products have challenges either from commercial or regulatory perspective. The third group of products performed inconsistently or provided low levels of control. This group includes Ranman Top, HDCF259, AHDB9702 and AHDB9959. Although many of these products did not provide satisfactory consistent control, in the absence of alternative options these can be used in mixtures with other products to improve resistance management when devising downy mildew control programmes.

Lastly, the group of products consisting of Subdue, HDCF256, HDCF257, HDCF258, Infinito, AHDB9845 and the two elicitor products FytoSave and Romeo should be considered carefully in the future, as the low control levels in the trial may have been because of product specific mode of actions or selectivity against the pathogen and more critically, timing of applications being post inoculation. This last group of products may have more to offer in a preventative programme prior to pathogen infection and this should be investigated.

In other trials at the National Cut Flower Centre in 2022, AHDB9702, AHDB9701, AHDB9747 and Frutogard were tested at 3 different growth stages to check for phytotoxicity on 4 varieties/colours of column stocks. Treatments were applied at elevated dose rates during the first two timings for a thorough test. Products applied on 3 June, during vegetative growth, were used at 4x recommended label dose rate in 800L/ha water volume, at flower bud formation (20 June) the products were tested at 2x recommended dose rate in 1,000L/ha and at 20% open flower (8 July) the products were tested at the full label dose rate in 1,000L/ha. Despite the hot and sunny weather conditions during and after application, none of the products tested displayed any phytotoxicity which was very positive outcome. Frutogard did leave a slight white deposit on the foliage but this did not affect the marketability of the flower stems.

AHDB

AHDB

Average levels of disease control achieved in stocks by different products for the downy mildew pathogen collected from a range of geographical locations for trials between 2018 and 2023

Crop management

In the UK, both early and late planted column stock crops are at risk of infection from downy mildew. However, the highest risk of infection is associated with late planted crops.

As with all downy mildew diseases, leaf wetness (including condensation on the leaf surface) is the most important factor that encourages the disease. If the leaf wetness duration can be reduced to below four hours on most days, the risk of infection is lessened. Consider adopting the following measures:

- Plant young plant material as soon as it is delivered and avoid cold storage if possible

- If cold-stored, ensure the cold store temperature setting is between 2–4°C and the young plant material is weaned before it is taken into a warm glasshouse (take out the cold stored product the night before the day of planting)

- Ventilate structures as much as possible and ensure sufficient airflow through the crop

- Use fans to move air around the structure where natural ventilation is limited and air may be stagnant

- Avoid extreme temperature fluctuations, which will exacerbate leaf condensation

- Avoid overhead irrigation from midday onwards and especially during the evening or at night

- Switch from full overhead to spot watering and then to trickle irrigation as soon as crop establishment allows.

c/o Lyndon mason

c/o Lyndon mason

Use of trickle irrigation helps to keep crop foliage dry

Disease control strategies

An integrated crop management approach is required to control downy mildew diseases on crops and cultural control measures must be combined with a robust fungicide programme to manage the pathogen. Several appropriate cultural control measures are described below.

Varietal resistance in column stocks

Unfortunately, none of the commercially grown varieties are known to be resistant to the pathogen, although differing levels of susceptibility have been observed.

Nursery hygiene

All production areas, tools, benches, trolleys and glasshouse structures should be disinfected before new crops are planted. It is important to note that, if reused, crates or any other production materials can act as sources of infection and the background disease pressure will quickly build up if not addressed. All crop debris should be thoroughly swept up and disposed of and any weeds removed.

Crop nutrition

Ensure that the residual level of available nutrients in the soil from previous cropping is not too high (see table 1 below). If the previous crop received an intensive balanced fertiliser regime with high ammonium content, it is advisable to delay fertigation to the column stock crop for the first couple of weeks to allow ammonium levels to deplete within the soil. Afterwards, provide a constant liquid feed of 150–200 ppm of nitrogen using a 14-0-14 (NPK) liquid feed, reducing levels to 50–100 ppm nitrogen as flowers develop.

As a crop, column stocks are only moderately demanding in terms of nutrients and additional nitrogen in the early crop stage will encourage soft growth and increase disease susceptibility. Moreover, use of phosphorus-rich proprietary liquid fertilisers will also encourage excessive growth. It is important to deliver the small amount of phosphorus required via foliar feeds and use fast-acting, highly mobile phosphite-based fertilisers. No more than five applications of phosphite base fertilisers should be used, especially under cool conditions, because this may result in stunted growth and a change of leaf colour to bronzed/ dark blue. Once the crop has reached 10–15 cm in height, it is recommended to use an additional potassium foliar fertiliser to help tone plants and improve flowering.

Table 1. Base fertliser applications based on nutrient level soil indicies for cut flower column stocks (RB 209, 1988)

|

Base dressing |

Nitrate, phosphorus, potassium or magnesium index |

||||||

|

|

0 |

1 |

2 |

3 |

4 |

5 |

Over 5 |

|

|

g/m2 |

||||||

|

Ammonium nitrate |

30 |

15 |

Nil |

Nil |

Nil |

Nil |

Nil |

|

Triple superphosphate |

150 |

140 |

130 |

110 |

80 |

45 |

Nil |

|

Sulphate of potash |

350 |

300 |

240 |

130 |

Nil |

Nil |

Nil |

|

Kieserite |

240 |

210 |

160 |

80 |

Nil |

Nil |

Nil |

Use of plant protection products

Devising downy mildew spray programmes for column stock crops

Foliar-applied fungicide products remain the cornerstone of downy mildew control for most growers. Unfortunately, the number of different active ingredients available in the UK has reduced over the last few years, making it more difficult to create robust control programmes covering several months of production. For effective control, it is important that:

- Growers obtain fungicide application records from their plug suppliers (covering active ingredient/product used, rate applied, timing of application) and take these into account when creating their own fungicide programmes

- Fungicides are used in combination with the other cultural control measures outlined in this guidance

- Products with an appropriate mode of action are selected to achieve the desired effect, taking into account crop growth stage, any signs of disease development and application method

- Programmes based on protectant fungicides are implemented three to five days after planting and before the onset of any disease symptoms

- Fungicides from at least three different fungicide FRAC groups are used (see Table 4)

- Products from different groups are used in tank mixes (where manufacturers permit this), or alternated within spray programmes

- The spray interval is reduced (for example, from 14 to seven days) when environmental conditions favour downy mildew (and is reduced to less than seven days when the temperature is between 15°C and 21°C and relative humidity is above 70%, or during long periods of leaf wetness)

- Spray applications achieve good coverage of leaves (both upper and lower surfaces) throughout the crop canopy

- Where rapid vegetative growth occurs in the early stages of the crop while using overhead irrigation, the intervals between spray applications are shortened, especially under favourable environmental conditions, to protect new growth

Once a crop is infected, the lack of effective eradicant fungicides makes it very difficult to eradicate the pathogen. However, it is possible to reduce infection of new extension growth by utilising integrated crop management practices and applying fungicides with anti-sporulant activity.

The fungicide products currently available for use against downy mildew diseases in the UK are summarised in Table 3 below. Example fungicide programmes are shown in Table 4 below, along with general guidance.

Adjuvants, water volumes, spray quality and application methods

-

Adjuvants

Some active ingredients do not require the addition of adjuvants; for example, those products pre- formulated with an adjuvant, or fully systemic active ingredients such as fosetyl-aluminium, metalaxyl-M and propamocarb-hydrochloride. A number which are contact in action, for example, mancozeb, will benefit from the addition of adjuvants such as organosilicons and anionic surfactants. Where active ingredients have locally systemic properties, it is best to tank-mix with non-ionic adjuvants, such as Activator 90, to help the active ingredient to penetrate through the leaf cuticle. Certain active ingredients perform better in acidic conditions and it is recommended, where possible, to utilise acidifying adjuvants such as Li-700 see Table 2 below.

- Water volumes

Most of the products outlined in Table 3 have Extensions of Authorisation for Minor Use (EAMUs) permitting their use. It is always recommended to refer back to the original label recommendations if water volumes are not mentioned in the EAMU. EAMUs for some products specify a higher water volume and it is a legal requirement to follow these guidelines. For products where a minimum water volume is stated and no maximum, growers must consider the mode of action of the product, the level of crop canopy development and crop growth stage when making a decision about the water volume to be used (table 2 and the figure below).

Note, the optimal water volume suggested is often below the volume used in commercial practice.

Table 2. Water volume and adjuvant requirements for a range of foliar-applied fungicides with activity against downy mildew pathogens

|

Example product |

Active ingredient |

Specific requirement on water volume (L/ha) |

Optimal performance water volume (L/ha) |

Advice on adjuvant selection |

|

Amistar |

Azoxystrobin |

Min 200 |

400–600 |

Surfactants required (Activator 90) |

|

FytoSave |

COS-OGA |

1,000 |

1,000 |

Surfactants required (Activator 90) |

|

Fubol Gold WG |

Mancozeb & metalaxyl-M |

Min 250 |

600–800 |

Acidifiers required (Li-700, Ranger, X-Change) |

|

Manzate 75 WG |

Mancozeb |

Min 500 |

1,000 |

Acidifiers required (Li-700, Ranger, X-Change) |

|

Paraat |

Dimethomorph |

Min 600 |

600–1,000 |

Surfactants required (Activator 90, organosilicons) |

|

Percos |

Ametoctradin & dimethomorph |

Max 1,000 |

500 |

Surfactants required (Activator 90, organosilicons) |

|

Previcur Energy |

Fosetyl-aluminium & propamocarb hydrochloride |

Min 200 |

500–1,500 |

Not required |

|

Proplant |

Propamocarb hydrochloride |

1,500 |

1,500 |

Not required |

|

Ranman Top |

Cyazofamid |

Min 600 |

1,200 |

Not required |

|

Revus |

Mandipropamid |

Min 200 |

400–600 |

Surfactants required (Activator 90, organosilicons) |

|

Romeo |

Cerevisane |

Min 100 |

800 |

Not required |

Silsoe spray applications unit

Silsoe spray applications unit

Uniform spray droplet distribution using the optimum water volume

- Spray quality and application methods

Generally, all fungicides are applied as a fine to medium spray, attaining a droplet size of 100–200 microns.

Although the nozzle choice will help with the delivery of the product to the correct area, it is the water volume and pressure that will make the largest impact. Generally, two to three bars at the nozzle and constant pressure is required to deliver accurate application volumes. Although most column stock growers utilise hand-held equipment that is difficult to calibrate, it is crucial that this is undertaken at least once every two months to ensure the correct water volume and delivery of the fungicides. The benefit of hand-held equipment is its ability to deliver products with contact or locally systemic action under the leaves, by directing the spray slightly horizontally. Products can also be delivered into the canopy using the air turbulence generated by the action of the applicator.

ADAS

ADAS

Variable nozzle type applicators are common in the cut flower industry

ADAS

ADAS

Avoiding fungicide resistance

It is important to adopt a robust anti-resistance management strategy by alternating products from different fungicide groups and by strictly following the FRAC UK guidelines, where relevant.

The development of fungicide resistance is a real risk in downy mildew pathogen species, especially when specific fungicides are used intensively and are insufficiently rotated with other products. The most at-risk groups are the phenylamides (Fubol Gold) and strobilurins (Amistar), as outlined in Table 4. To minimise the risk of selecting resistant pathogen strains, it is recommended that:

- Fungicides alone are not used for disease control; cultural control methods, varietal selection (where relevant) and good enhanced foliar nutrition should be part of the holistic approach to controlling the pathogen

- Fungicides are used according to the programmes shown, or similar programmes designed to avoid resistance development

- No more than two sprays of the same fungicide or fungicide group are used in sequence; thereafter, a fungicide from a completely different fungicide group is used

- No more than 50% of the total sprays applied to the crop are strobilurin fungicides

- The label and EAMU recommendations are carefully followed, especially those concerning the dose rate and water volumes

Table 3. Foliar applied fungicides available in the UK with activity against downy mildew pathogens

|

Product name |

Active ingredient |

Eradicant/ protectant activity |

Outdoor/ protected use |

Maximum number of applications |

Water volume (L/ha)* |

Dose rate |

Concentration |

Approval status |

Expiry date |

|

Amistar |

Azoxystrobin |

E/P |

Outdoor/ protected |

4 |

500 (min 200) |

1 L/ha |

2 ml/L |

EAMU 3388/18 |

30/06/2027 |

|

FytoSave |

COS-OGA |

P |

Outdoor/ protected |

8 |

1,000 |

3 L/ha |

3 ml/L |

EAMU 1911/19 |

22/10/2032 |

|

Fubol Gold WG |

Mancozeb + metalaxyl-M |

E/P |

Outdoor/ protected |

3 |

700 (min 250) |

1.9 kg/ha |

2.7 g/L |

EAMU 2133/21 |

09/09/2099 |

|

Manzate 75 WG |

Mancozeb |

P |

Outdoor/ protected |

8 |

1,000 (min 500) |

2 kg/ha |

2 g/L |

On label |

30/07/2026 |

|

Paraat |

Dimethomorph |

P/anti- sporulant |

Protected |

2 |

800 (min 600) |

0.36 kg/ha |

0.45g/L |

EAMU 2585/11 |

15/08/2027 |

|

Percos |

Ametoctradin + dimethomorph |

P/anti- sporulant |

Outdoor/ protected |

4 |

1,000 |

0.8 L/ha |

0.8 ml/L |

EAMU 0962/21 |

15/08/2027 |

|

Previcur Energy |

Fosetyl-aluminium + Propamocarb hydrochloride |

E/P/anti- sporulant |

Outdoor/ protected |

2 |

1,000 (min 200) |

2.5 L/ha |

2.5 ml/L |

EAMU 1845/13 |

31/01/2026 |

|

Proplant |

Propamocarb hydrochloride |

P |

Outdoor/ protected |

3 |

1,500 |

1.5 L/ha |

1 ml/L |

EAMU 0785/16 |

31/01/2026 |

|

Ranman Top |

Cyazofamid |

P/anti-sporulant |

Outdoor/ protected |

6 |

1,000 (min 600) |

0.5 L/ha |

0.5 ml/L |

EAMU 3299/22 |

09/09/2099 |

|

Revus |

Mandipropamid |

E/P/anti- sporulant |

Outdoor/ protected |

1 |

500 (min 200) |

0.6 L/ha |

1.2 ml/L |

EAMU 2763/16 |

31/01/2026 |

|

Romeo |

Cerevisane |

P |

Outdoor/ protected |

8 |

750 (min 100) |

0.75 kg/ha |

1 g/L |

EAMU 1455/21 |

23/10/2032 |

* Optimal water volume followed by specific approval requirement in brackets (if different). A water volume of 1,000 L/ha is often common practice in industry for many products.

This table includes information available on the Health and Safety Executive (HSE) website (pesticides.gov.uk), on product labels and in supplier technical leaflets. Please check the HSE website or with an appropriate adviser before using the information as regulations may have changed.

EAMU – Extension of Authorisation for Minor Use.

Growers must hold a paper or electronic copy of an EAMU before using any product under the EAMU arrangements. Anyone using a plant protection product via an EAMU should follow EAMU (or label) recommendations. Use is carried out at the grower’s own risk. If specific crop safety information is not available, consider undertaking small-scale trials and/or obtain professional advice before widespread commercial use.

If in doubt about which products are permissible, or how to use them correctly, seek advice from a BASIS-qualified consultant.

Table 4. Mode of action and resistance risk potential for fungicides with activity against downy mildew pathogens

|

Fungicide group |

Example active ingredients and products |

FRAC Code |

Mode of action and mobility |

Resistance risk |

|

Carboxylic acid amides (CAA fungicides) |

Dimethomorph (Paraat, Percos, second active); mandipropamid (Revus) |

40 |

Interferes with phospholipid biosynthesis and cell wall deposition Locally systemic |

Resistance known in Plasmopara viticola Cross-resistance between all members of the CAA group Low to medium risk |

|

Carbamates |

Propamocarb hydrochloride (Previcur Energy, second active, Proplant) |

28 |

Affects cell membrane permeability Systemic |

Low to medium risk Resistance management required |

|

Dithiocarbamates |

Mancozeb (Fubol Gold WG, first active, Manzate 75WG) |

M3 |

Multisite inhibitor Protectant, non-systemic |

Generally considered to be a low risk group with no signs of resistance to the fungicides developing No resistance detected Have been used globally since the 1960s |

|

Microbial |

Cell walls of Saccharomyces cerevisiae strain LAS117 – Ceravisine (Romeo) |

P06 |

Microbial elicitors with protectant mode of action. Host plant defence induction |

Resistance not known. |

|

Not Specified |

Chito-OligoSaccharides + Oligo-Galacturonic Acid -COS-OGA (FytoSave) |

NC |

Natural extracts which mimic pathogen infestation |

Resistance not known. |

|

Phenylamides (PA fungicides) |

Metalaxyl-M ( Fubol Gold WG, second active) |

4 |

Single-site inhibitor Interferes with synthesis of ribosomal RNA Systemic |

Resistance and cross-resistance well known in various oomycetes, but mechanism unknown High risk |

|

Phosphonates |

Fosetyl-aluminium (Previcur Energy, first active) |

P07 (33) |

Spore germination inhibitor Systemic and anti-sporulant. Host plant defence induction |

Few resistance cases reported in fungal species Low risk Reclassified from U33 in 2018 |

|

Quinone inside inhibitor (QiI fungicides) |

Cyazofamid (Ranman Top) |

21 |

Spore germination inhibitor with moderate translaminar and curative activity |

Resistance risk unknown but assumed to be medium to high risk. Resistance management required. |

|

Quinone outside inhibitor (QoI fungicides) |

Azoxystrobin (Amistar);

|

11 |

Single-site inhibitor Inhibits fungal respiration Locally systemic |

Resistance known in various fungal species Cross-resistance shown between all members of the QoI group High risk |

|

Quinone outside inhibitor, stigmatellin binding type (QoSI fungicides) |

Ametoctradin (Percos, first active) |

45 |

Mitochondrial respiration inhibitor Locally systemic |

Not cross-resistant to QoI fungicides Resistance risk assumed to be medium to high (single-site inhibitor) Resistance management required |

FRAC – Fungicide Resistance Action Committee

Table 5. Example production and fungicide programmes for early and main season crops of column stocks

|

Early season crops |

February |

March |

April |

||||||

|

Spray application |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

|

Product* |

Manzate 75 WG + Romeo |

Previcur Energy |

Percos |

Amistar + Paraat |

Manzate 75 WG (2) + Romeo (2) |

Ranman Top + Paraat |

Revus + Romeo (3) |

Amistar (2) + Ranman Top (2) |

Percos (2) |

|

FRAC group |

M3 + P06 |

28 + P07(33) |

45 + 40 |

11 + 40 |

M3 + P06 |

21 + 40 |

40 + P06 |

11 + 21 |

45 + 40 |

|

Liquid fertiliser regime |

14-0-14 (20-5-30) @200 ppm N |

9-9-36 @100 ppm N |

|||||||

|

Foliar fertiliser regime |

Phosphite |

None |

Phosphite |

None |

Phosphite |

None |

Phosphite |

Phosphite |

None |

|

Irrigation regime |

Overhead |

Overhead |

Overhead + drip |

Overhead + drip |

Drip |

Drip |

Drip |

Drip |

Drip |

|

Main season crops |

April |

May |

June |

||||||

|

Spray application |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

|

Product* |

Percos + FytoSave |

Manzate 75 WG + FytoSave (2) |

Previcur Energy |

Percos (2) |

Previcur Energy |

Amistar + Ranman Top |

Manzate 75 WG (2) + Revus |

Amistar (2) + Paraat |

Ranman Top (2) + Proplant |

|

FRAC group |

45 + 40 + NC |

M3+NC |

28 + P07(33) |

45 + 40 |

28+P07(33) |

11 + 21 |

M3 + 40 |

11 + 40 |

21 + 28 |

|

Liquid fertiliser regime |

14-0-14 (20-5-30) @200ppm N |

9-9-36 @100ppm N |

|||||||

|

Foliar fertiliser regime |

Phosphite |

None |

None |

Phosphite |

Phosphite |

None |

Phosphite |

None |

Phosphite |

|

Irrigation regime |

Overhead |

Overhead |

Overhead + drip |

Overhead + drip |

Drip |

Drip |

Drip |

Drip |

Drip |

* Bracketed numbers refer to product application number within the programme

This table has been created for demonstration purposes only and adoption should take into account site and crop specific requirements.

This table includes information available on the Health and Safety Executive (HSE) website (pesticides.gov.uk), on product labels and in supplier technical leaflets. Please check the HSE website or with an appropriate adviser before using the information as regulations may have changed.

Growers must hold a paper or electronic copy of an EAMU before using any product under the EAMU arrangements. Anyone using a plant protection product via an EAMU should follow EAMU (or label) recommendations. Use is carried out at the grower’s own risk. If specific crop safety information is not available, consider undertaking small-scale trials and/or obtain professional advice before widespread commercial use.

If in doubt about which products are permissible, or how to use them correctly, seek advice from a BASIS-qualified consultant.

General guidance when devising spray programmes for downy mildew control on column stocks

- Fungicide selection should take into account the product mode of action, prevailing weather/environmental conditions and stage of crop growth

- The aggressive nature of the pathogen means that growers are advised to adopt a strict fungicide programme, even if there are no visible symptoms in the crop

- For successful management of downy mildew, any fungicide programme should begin early. The first spray application should occur as soon as possible after planting

- During the early growth stage, it is recommended to apply products based on active ingredients with contact modes of action (azoxystrobin, cyazofomid, mancozeb). This will allow the accurate application of such products while the crop canopy is more open to achieve thorough coverage

- Growers should continually assess spray application intervals because sporulation following infection can occur within five to six days, especially under favourable conditions

- Column stocks are generally slow-growing, but the period immediately after planting and two weeks prior to harvest are ‘rapid growth stages’ and plants can tolerate downy mildew to a certain extent. Fungicides with anti-sporulant activity play a key role at this stage because they will supress further infections occurring later on when plant growth slows down

- During the rapid growth stage it is important for growers to take into account the crop liquid fertiliser regime. Where growers apply proprietary fertilisers, the phosphorus content can trigger a quick growth response if temperature conditions are above 8°C. It is worth switching to potassium boosters, such as 20-5-30, or plant finishers, such as 9-9-36, and delivering the phosphorus content with foliar-applied fertilisers based on phosphites, which can be tank-mixed with most fungicides

- Please note, where fungicides with fosetyl-aluminium actives are used, it is not recommended to mix these with phosphite-based foliar fertiliser

- Once the flower buds start to open in the latter stage of production, growers should be aware of potential spray deposits. Some solid formulation fungicides (WP, WG and WDG) are likely to leave deposits

- As all available fungicide products are used under Extensions of Authorisation for Minor Use (EAMUs), the products are applied at the grower’s own risk. If used for the first time, small-scale applications to check for toxicity are strongly recommended.

As a result of the prevailing temperatures experienced during the early crop, the potential for downy mildew sporulation is low at the beginning of the production cycle but will rapidly increase towards the end. In the case of this crop, the interval between fungicide applications can be more generous during the first half of the production cycle but should be reduced towards the end, to reflect the favourable conditions for disease development. The later planted main crop of column stocks will require a more intensive spray programme, with reduced intervals between fungicide applications. So, for example, the early crop may receive 8–10 spray applications, while the main crop receives 9–12 applications, depending upon the production techniques and nursery hygiene protocols employed, varietal selection, source of plant material and background disease pressure.

Useful links and resources

Authors

Original author Lyndon Mason with assistance from Phil Jennings, Fera

Update author Selchuk Kurtev