Please click here to access the main AHDB website and other sectors.

The NIAB EMR WET Centre: Work programme and results for 2019

Friday, 10 July 2020

The WET Centre demonstrates ‘Best Practice’ in irrigation and fertigation technology in strawberry. Much of the technology on show has been developed by AHDB and other funded projects which aimed to improve water use efficiency in bag-grown strawberry and container-grown raspberry. AHDB is one of a number of part-funders of the WET Centre.

The Centre allows the results of other research and development to be demonstrated and put into a commercial type production system. This also enables AHDB to demonstrate some of its other research on strawberry and raspberry to be adopted in a commercial cropping situation. Each year, the WET Centre funders work closely with Dr Mark Else at NIAB EMR to develop a work programme for the season, selecting specific technologies and approaches to demonstrate and compare in a range of growing systems.

In 2019, the following work investigations and comparisons were made using the everbearer variety Malling™ Champion, from the East Malling Strawberry Breeding Club, which is part funded by AHDB. It was planted in coir bags of 18 litre volume at a density of 9 plants per bag.

Irrigation water use efficiency

We compared the application of irrigation water to the bags at both 5% and 10% run-off. Throughout the trial, the 5% regime was maintained between 2-5% run-off and the 10% regime between 8-15%. The moisture content was generally maintained between 0.6 and 0.7 m3.m-3 in both treatments.

The coir pore E.C. rose throughout April-June in each treatment. A flushing event was applied in early July and two more later in July (using 13-14 litres per bag) to manage coir pore E.C. values. The pore E.C. in the 5% treatment was slightly higher than the 10% treatment throughout August and September 2019.

Results:

- There were no consistent or significant effects of 5% versus 10% run-off on leaf levels of nitrogen (N), phosphorus (P) or potassium (K)

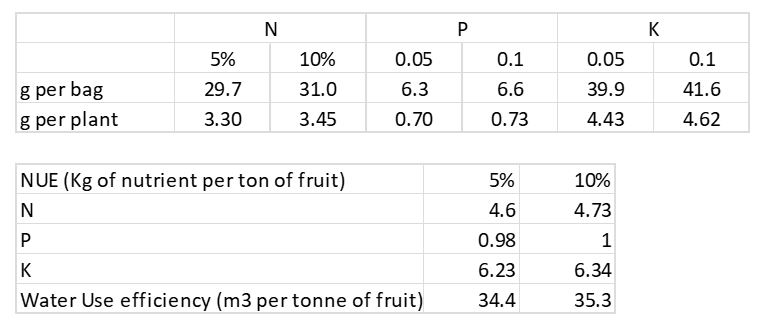

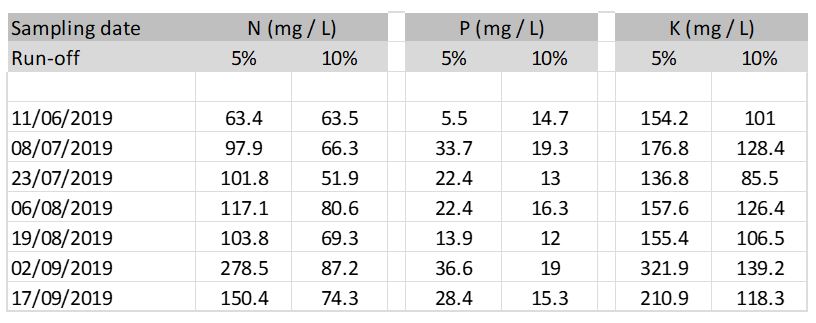

- The total NPK applied in each treatment is given below, as are the water and fertiliser use efficiency values (g added per Kg of Class 1 fruit produced)

- Coir data - The results from the coir analyses over the growing season are given below.

- The yield per plant was around 720 g with 145 g of waste per plant and 83% Class 1 grade-out

- There were no statistically significant yield differences between the 5% and 10% run-off treatments

Comparing dripper number per bag

In 2019, eight 0.5 L/hr drippers per bag were compared to five 1.2 L/hr drippers per bag to investigate if the higher number of drippers improved the availability of water throughout the substrate in the bag. It was found that although the eight drippers produced a higher level of run-off, there were no statistically significant differences in yield.

Studying tunnel phytoclimates and the effect on yield performance

We are investigating how plant performance, Class 1 yields and berry quality are influenced by row position, and we are trying to understand how the conditions surrounding the plant (the phytoclimate) vary in different zones within the polytunnel. To that end, we installed 18 sensors that measure photosynthetically active radiation (PAR), air temperature and relative humidity (RH) to monitor and quantify the zonal phytoclimates in Tunnel #2. The aim was to monitor and map the different zonal phytoclimates within the polytunnel so that we can better manage the environments to optimise crop productivity across the growing area.

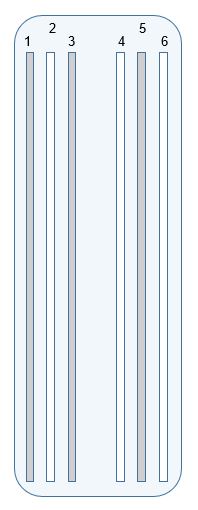

In explaining the results, the diagram below will help the reader to understand the row positions in this tunnel. Rows 1 and 6 are leg rows, and rows 3 and 4 are centre rows.

The yields produced in each of the six rows within the tunnels were recorded and the differences between the row positions compared. Plants in each Row 4 had a statistically significantly higher Class 1 yield than those in the other rows (different letters denote statistical significance between yield values). As you can see, Row 4 had 18% higher Class 1 yield than Row 1.

Tunnel

Row # Class 1 (g / plant)

1 653d

2 703c

3 725bc

4 796a

5 755ab

6 688cd

Studying the effect of phytoclimate in the tunnels on plant water use demonstrated that plant water use in Rows 2 and 5 was lower than that in the leg rows or the centre rows. This result raises the question as to whether each row (or zonal phytoclimate) should be irrigated or fertigated separately to match supply with plant demand.

We’re also interested in developing smart venting control to optimise the phytoclimate within different sections of the polytunnel, and we’ll continue to assess the potential of using rainwater harvesting to improve local water security.

Powdery mildew prediction

AHDB has funded a number of projects to improve the management and control of strawberry powdery mildew. In projects SF 62 and SF 62a, a model was developed to predict periods when the crop is at risk of infection. It relies upon the measurement of the numbers of hours of optimum temperature and humidity for disease development and helps growers to identify the best time to apply protective sprays to prevent infection from occurring. The system has been tested in commercial strawberry production and in a further AHDB project (SF 157), where it helped to reduce the number of spray applications required to gain effective control.

A similar comparison was demonstrated at the WET Centre in 2019 on the everbearer variety Malling™ Champion where six out of eight tunnel bays were sprayed routinely for powdery mildew control and two out of eight used the managed approach, overseen by Angela Berrie (NIAB EMR plant pathologist) and Alex Cooke (Berry Gardens agronomist). The managed approach used three fewer fungicide sprays over the course of the season. Further details can be read on the powdery mildew section of this site.

Raspberry WET Centre

Four new automated venting polytunnels have been erected to house Malling™ Bella and Malling™ Charm – two new primocane raspberry releases from the East Malling Rubus breeding programme. Precision irrigation is being deployed to optimise coir moisture content, average daily run-off, and coir pore E.C. in these varieties, and to see whether quality and shelf-life potential can be further improved under precision irrigation.