Please click here to access the main AHDB website and other sectors.

- Home

- Knowledge library

- Managing residues from historic CIPC use in potato stores

Managing residues from historic CIPC use in potato stores

Following non-renewal in the EU, final use of products containing chlorpropham (CIPC) had to be completed in GB by 8 October, 2020. After this date it became illegal to store or use CIPC containing pesticides. CIPC was GB’s most common sprout suppressant and, because of its stability there is a risk that future crops will become contaminated.

Residue levels

A maximum residue level (MRL), is the largest amount of a chemical residue that is allowed to be detected on a product. Any amount over that level would exceed the MRL, meaning it is illegal to trade or market that commodity.

In the EU, a temporary Maximum Residue Level (tMRL) of 0.4ppm was introduced on 2 September 2021. In the EU the maintenance of the tMRL, or the establishment of a new, lower one is based on the submission to EFSA of an annual report on stored potato CIPC residue surveys, and the adoption of effective cleaning methods for CIPC residue reduction. It is the European Commissions’s intention that stores do not contribute CIPC residues above the Limit of Quantification (LOQ) value (0.01ppm), in line with other unapproved pesticides.

Data from UK stores was submitted and helped towards the establishment of this tMRL. However, Brexit took place before transposition into law and so the tMRL does not apply in GB and the MRL remains at 10ppm. A similar approach using a tMRL is anticipated to be used in GB.

This page was last updated in December 2021. Refer to the Health and Safety Executive, Chemicals Regulation Division (CRD) website for more detailed, up-to-date information on MRLs.

Research report on the longevity of CIPC residues in store fabrics

Cleaning Guidelines

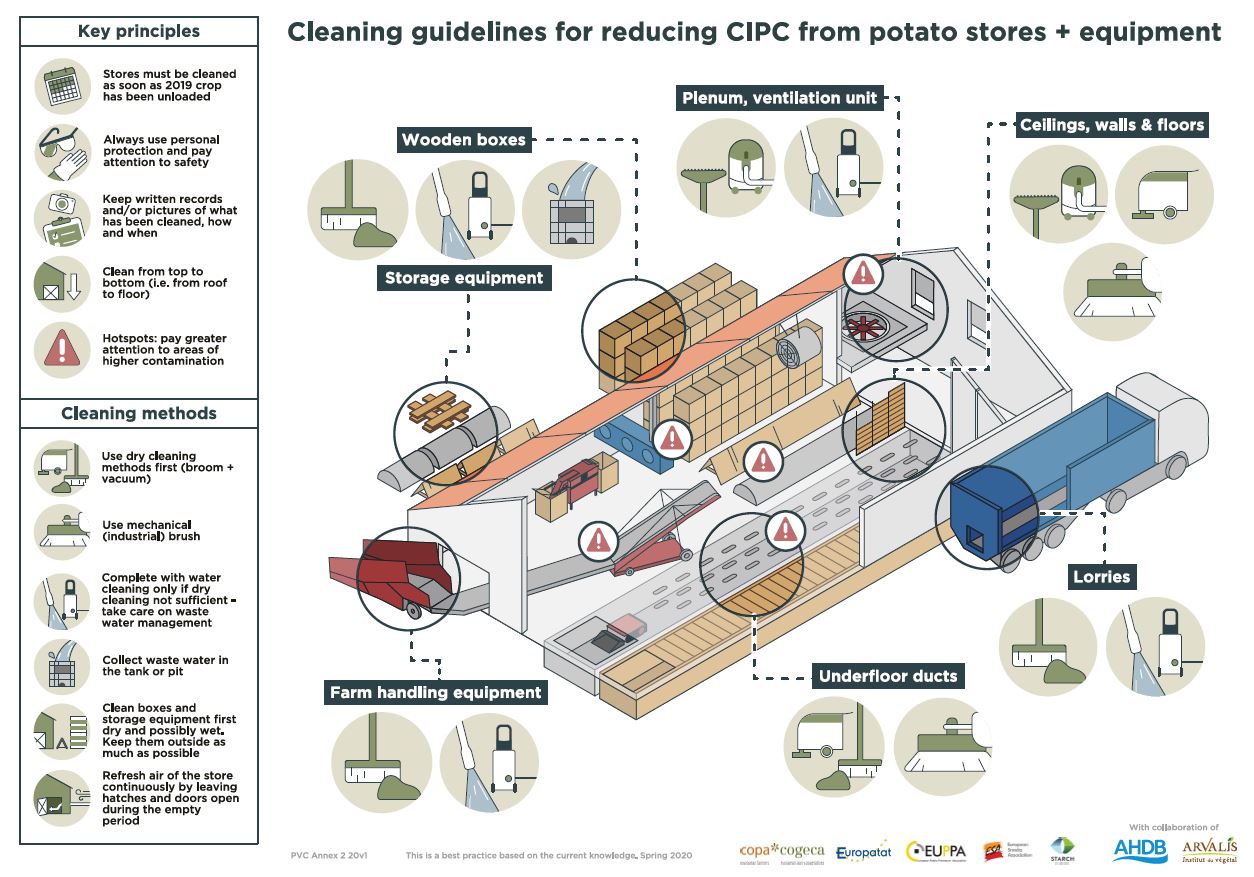

Guidelines were produced, in collaboration with European industry bodies (the Potato Value Chain or PVC) to reduce traces of CIPC in potato stores and to reduce the risk of exceedance of any future tMRL.

- All stores with a history of CIPC use must be cleaned

- Cleaning activities must be carried out safely: always use personal protective equipment (PPE) and pay particular attention when working at height.

- Keep written records and pictures of what has been cleaned, how and when. Buyers of potatoes may request a record of cleaning activities.

- Preferably use dry cleaning methods and in any case start with them. Only if no suitable dry cleaning method is available, or not sufficient, should water be used. When using complementary wet cleaning, an acceptable method of collecting and disposing of water must be used to avoid dispersing CIPC into the environment.

- Care should be taken to minimise re-distribution of CIPC. Loose materials should be removed promptly, by vacuuming. Sweeping and brushing generate dust, which risks re-distribution.

- Cleaning must be carried out from top to bottom (i.e. roof to floor).

- CIPC is only slightly volatile. Volatilisation will contribute to removal of CIPC, but over longer periods of time. When the store is not in use for potato storage, doors and hatches should be left open to allow for continuous air exchange.

- Underground cleaned ducts should also have a constant movement of air after cleaning, either by running fans or by natural draft. Low airspeed is sufficient.

- Where possible, first remove loose waste material by dry cleaning and then move store hardware (boxes, above ground ducts, etc.) outside so weather action (sun, rain, wind, temperature) can also contribute to CIPC removal.

- Cleaning efforts should focus on positions of highest contamination, like plenums and fans.

An infographic, visual guidelines and a checklist on store cleaning have been produced.

If you are using a professional cleaning company to clean your stores - pass them this information

Infographic

A visual representation of the key principles for the reduction of CIPC from potato stores

Download an infographic version of the cleaning guidelines

Visual inspection guideline

Before and after cleaning pictures from real stores. These may help you or your staff to assess whether stores have been adequately cleaned.

Download the visual inspection guidelines

Store cleaning checklist

A document for you to track your cleaning activities and to share with the buyer/processor after cleaning.

Safety First

Effective store cleaning is likely to be associated with a number of risks that will need to be controlled to ensure the safety of staff. We recommend using the HSE website if you don’t already have a system for carrying out risk assessments, or need guidance on completing risk assessments.

Some of the areas may be ‘confined spaces’, which will require additional controls. Make sure you have a safe system of work, and that everyone involved is properly trained. In all stores, electrical isolators should be locked off when fans, dampers, guards etc are being cleaned.

Topics:

Sectors:

Tags: