Please click here to access the main AHDB website and other sectors.

- Home

- Knowledge library

- Management of bought-in cutting material to retain quality

Management of bought-in cutting material to retain quality

The majority of tender perennial, and an increasing range of hardy perennial unrooted cutting material, sourced from the Middle East, East Africa, South America and the EU, is imported into the UK each year. While there are many benefits associated with cuttings grown under high light conditions, quality problems can develop during delays in transit or because of incorrect storage, including loss of condition, dehydration and disease in cutting material.

Temperature, moisture, ethylene, carbohydrate levels and disease pressure all influence rooting success, during mother stock culture and onwards in the transit, storage and rooting stages. Of these, temperature and the presence of free water have the greatest effect; temperature affects plant respiration, water loss, ethylene production and pathogen pressure. Understanding the issues and improving the handling of cutting material on arrival at the nursery can increase cutting success, young plant viability and final plant quality.

Recent research in the US, Europe and the UK has focused on mitigating the adverse influences on cutting quality and root development, including depletion of carbohydrates in cuttings, cutting temperature, lack of turgor in cuttings, ethylene levels and the presence and control of pathogens.

Trials undertaken in the Bedding and Pot Plant Centre (BPPC) work programme focused on Pelargonium Green Leaf Series ‘Bianca’. The work indicated that effective rehydration (achieved via dip treatments) was shown to have significant beneficial effects on rooting and plant quality. Dip treatments may be suitable on a small scale, but are likely to prove impractical and uneconomic on a larger scale, in particular, where labour is in short supply or where sticking machines are used. In these situations, effective rehydration can be achieved by timely use of irrigation (misting/fogging/booms/hand lance) although care must be taken not to saturate the growing media post-sticking. Free-draining growing media may need to be specifically selected to avoid saturation. Based on such work, guidance is provided on the management of cutting material at the point of receipt, from cooling plant material through to sticking, and the influence on plant quality.

Prior to receipt of cutting material

Site hygiene: Prepare the cool room or refrigerator and the area designated for sticking operations, especially the propagation bench. Remove any plant debris and growing media and clean with a suitable disinfectant, such as Jet 5. Clean any tools used in the propagation process.

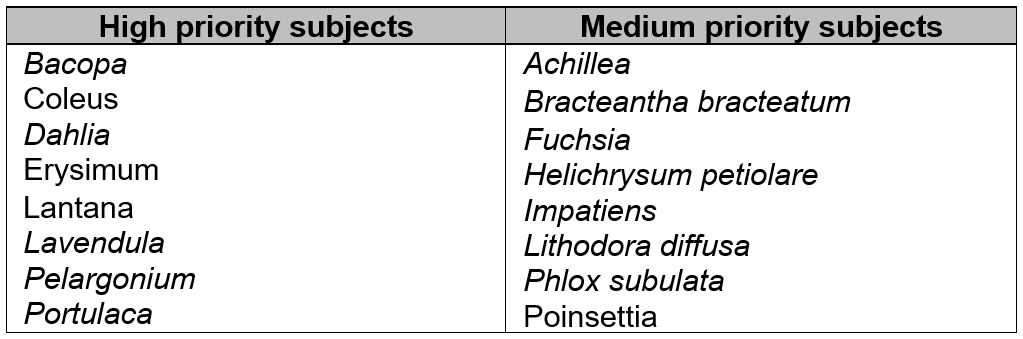

Prioritise incoming material: Create a prioritised sticking list prior to receipt of the plant material, based on sensitivity to ethylene and temperature, grouping plants as high, medium or low priority. A suitable schedule should be to stick high priority cuttings within four hours of arrival on the nursery, medium priority within 24 hours and low priority within 48 hours.

Cool room/refrigerator settings: Set and check the cool room parameters. Monitor the cool room regularly, ensuring a stable environment is maintained at the required temperature.

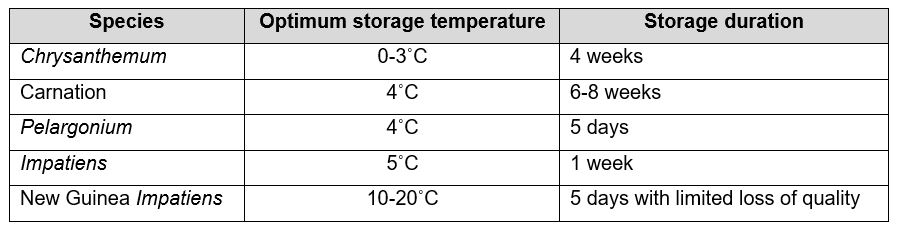

Cool room temperature: Temperatures should be appropriate for the plant species; it needs to be as low as possible, while avoiding chilling injury, to extend storage time while maintaining cutting quality. The optimum storage temperature is species dependent, however a compromise cool room temperature is often required that will accommodate a range of species. The most appropriate temperature will vary between seasons, as early spring and autumn flowering plants tend to be more cold tolerant than tender summer bedding subjects.

Symptoms of chilling injury include blackened or water soaked tissue, wilted foliage and stems and desiccated tissue following water loss.

Upon receipt of cutting material

When the cutting material arrives on the nursery open the container and any plastic coverings and agitate the cuttings to release any ethylene build-up within the container. Inspect the plant material for quality and liaise with the cutting supplier as required. Transfer plant material to the cool room or refrigerator until sticking.

Cutting treatments

- Ensure hygiene procedures are followed throughout the propagation process

- As a minimum, dip the cuttings in water only for five seconds (quick dip)

- Consider applying Rhizopon AA as a quick dip treatment (five seconds, six tablets/litre of water) to improve root development, particularly for Pelargonium. Rhizopon AA can be applied in a programme with sprays of Signum or Serenade ASO to improve cutting quality and suppress disease, but this will increase costs

- Rhizopon AA should not be applied as a long dip treatment

- Record sticking rates with and without dip treatments and estimate the labour cost to apply the treatments

- A range of rooting media (such as loose-fill growing media or preformed media in paper pots, glue plugs etc.) and rooting systems (mist, fog or boom, tented in polythene or covered in fleece) may be used. Each will place different stresses on the plant and any applications made to the cuttings will have different results dependent on the environment. Trial new treatments on a range of plant species before widespread commercial use

- If supportive environments are provided during the rooting process, wean plants as necessary afterwards

- Record rooting success rates by species and treatment

Other notes in this series:

Forcing herbaceous perennials for early spring sales

New plant growth regulators for use on pot- and pack-grown bedding plants

New plant growth regulators for use on poinsettia

The use of spectral filter polythene in bedding plant production

The use of spectral filter glass coatings in the production of protected ornamentals

Have a question? Ask the team ...

Sectors: