Please click here to access the main AHDB website and other sectors.

- Home

- Knowledge library

- The use of spectral filter glass coatings in the production of protected ornamentals

The use of spectral filter glass coatings in the production of protected ornamentals

Glasshouses are designed to maximise light transmission while minimising the effects of solar heating. However, the large differences in light levels that occur through the seasons means that crops can receive too much light and heat in the summer and insufficient light in the winter.

Removable glass coatings provide a flexible option for managing light transmission and altering the spectral properties of light within glasshouses. In an era of increasing summer temperatures, the use of glass coatings to reduce radiation entering the glasshouse has become even more relevant.

Coatings can be used to complement or replace screening, and modern coatings more accurately meet crop requirements. Coatings have traditionally been more widely used in continental Europe with typically higher summer temperatures and a better service infrastructure to apply and remove coatings safely and economically. With new build projects, consider glasshouse cleaning/coating equipment at the design stage.

Bedding and Pot Plant Centre research

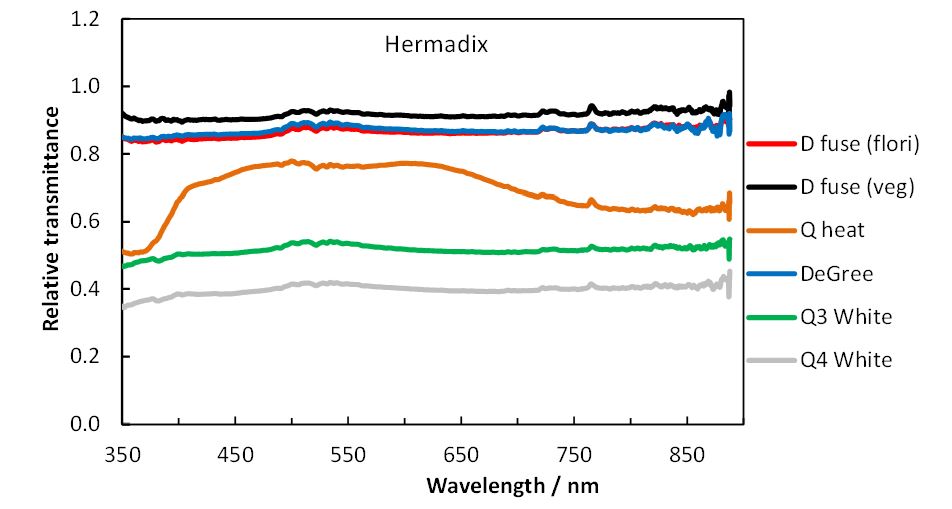

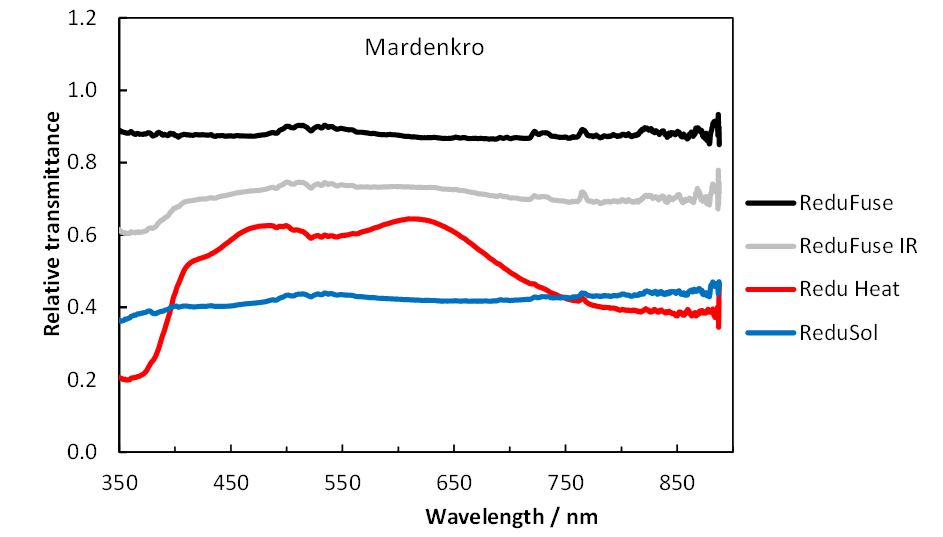

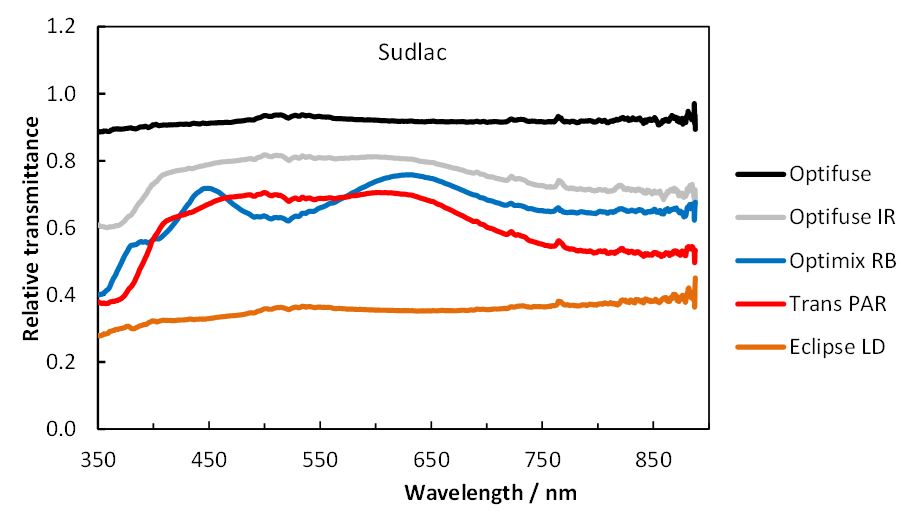

Trials carried out as part of the Bedding and Pot Plant Centre (BPPC) work programme characterised the effect of glass coating products on light quality and transmission, their ease of use and durability. Light transmission and spectra measurements were recorded for fifteen glass coating products alongside untreated standard and diffused glass. The products were sprayed onto new 3mm standard horticultural glass from a single batch. The glass was mounted on A-frames and exposed to the elements between April and November 2016. The following products were examined:

- Mardenkro: ReduFuse, ReduFuse IR, ReduHeat and ReduSol.

- Hermadix: D-FUSE Floriculture, D-FUSE, Vegetable, D-GREE, Q Heat, Q3, Q4.

- Sudlac: Optifuse, Optifuse IR, Optimix RB, TransPAR and Eclipse LD.

Observations on the effect of glass coatings on light intensity and quality

Light diffusion: Coatings designed to diffuse light (ReduFuse, D-FUSE, Optifuse) or to provide shading (Eclipse LD, ReduSol, Q3 and Q4) affect the total amount of light transmitted, but have little influence on light quality. However, while some products are designed specifically to diffuse light, all products were observed to diffuse light to some extent. Light diffusion can improve plant quality through increased light penetration into the crop, avoiding potentially damaging ‘hot spots’ of light and reducing plant stress.

Heat reduction: Products designed to reduce solar heating (Q Heat, TransPAR, ReduHeat) reduced transmission of light in the red region of the spectrum with wavelengths greater than 650 nm, and UV light (315 – 400 nm), predominantly UV-A. The reduction of UV transmission may have a greater impact on crop performance under UV transmitting plastic than glass, as glass itself removes UV light from the light transmitted.

Combined light diffusion and heat reduction: A number of products (D-GREE, Optifuse IR and ReduFuse IR) combined light diffusion with reflectance of near infra-red (NIR) and UV light. The measurements taken did not appear to suggest increased NIR reflectance by D-GREE compared with the D-FUSE products, however these measurements did not cover the entire NIR range, and so may be missing the region of the spectrum where this coating is most effective.

Optimix RB is designed to alter the colour balance of visible light. It stood out from other products due to its green hue (green light is reflected by this product), and there were noticeable peaks in the transmission spectra at about 450nm (blue) and 630nm (red). Transmission in the green region (500-550nm) was approximately 10% lower than in the red and blue region of the spectrum.

A comparison of the data for the untreated glass and untreated diffuse glass indicated that relative light transmission was similar for both materials. Diffuse glass naturally reflects a proportion of light.

Practical considerations for product application

Plan the use of glass coatings by first defining the effect required; light diffusion, reduced light intensity or solar heating. Determine the required duration, appropriate application rates and calculate the cost, including for glass cleaning, product application and removal. Closely monitor crop performance to determine the effectiveness of the treatments.

Clean new glass using a release agent such as Removit (Hermadix) or ReduClean (Mardenkro) before applying glass coatings. New glass is coated with silicon to make it easier to separate panes, however this can prevent glass coatings from adhering.

Light diffusing products (such as ReduFuse and TransPar) had a greater tendency to run at the dose rates used in the BPPC trial, however most products generally spread out as they dried to produce a fairly even coat. No difficulties were experienced with blocked nozzles.

Durability can be determined as the change in light transmission over the course a season. The BPPC trial showed that light transmission increased most in the shade products, Q3, Eclipse LD, ReduSol and Q4. Such weathering can be a benefit, allowing a gradual increase in light transmission as the season progresses. Duration can be adjusted by applying products at higher concentrations to increase duration.

Take a look at the different coatings applied to glass here

Other notes in this series:

Forcing herbaceous perennials for early spring sales

Management of bought-in cutting material to retain quality

New plant growth regulators for use on pot- and pack-grown bedding plants

New plant growth regulators for use on poinsettia

The use of spectral filter polythene in bedding plant production

Have a question? Ask the team ...

Sectors: