Please click here to access the main AHDB website and other sectors.

- Home

- Knowledge library

- Why should you use thermal storage?

Why should you use thermal storage?

There are various reasons for using thermal storage. Here, we discuss the benefits of storage, including more efficient heating systems, smaller heat generators and heating backup.

Back to: The basics of thermal storage for horticulture

To make heat generated now available at a later time

Heat-generating equipment may be used for a number of reasons, which might not always be primarily about a need for heat. For example, this could be the production of CO2 for plant growth, or where an engine is run to generate electricity.

Here, heat is a by-product of the primary process and might be produced when there is no heat demand in the glasshouse. Without storage, a grower may have to exhaust (or dump) this ‘waste’ heat to the atmosphere. With a thermal store, a grower can retain the heat from the daytime CO2 production period and use it during the night, when the ambient temperature falls and the heat demand of the glasshouse increases.

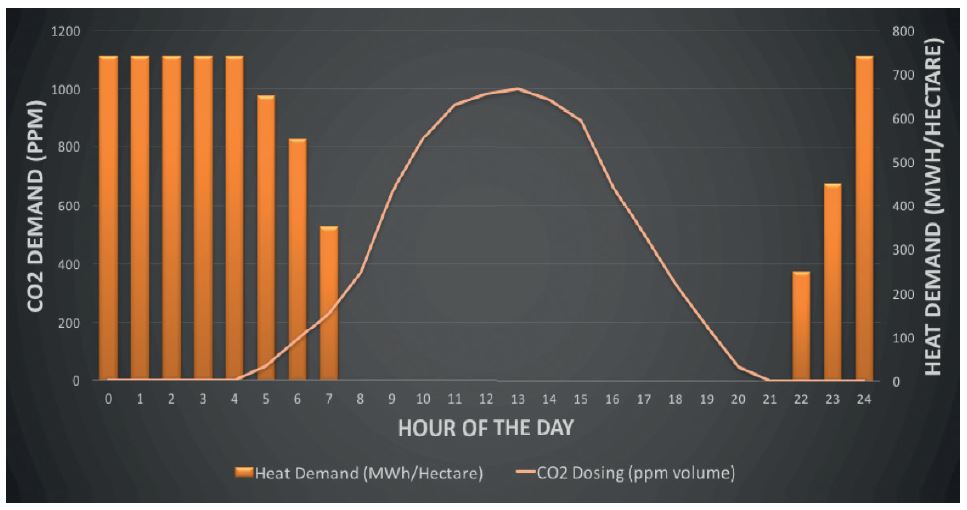

The fuel that would have otherwise been used in a boiler at night can thus be displaced by the stored energy, therefore saving money. Figure 1 shows the daily heat and CO2 demand in a typical salad-producing glasshouse and how the daily demand for CO2 and heat occur at opposite ends of the day.

Figure 1. The chart shows how heat demand occurs during the cold night and CO2 demand occurs during the day. It is economically beneficial to store the heat from the CO2 generation for use during the night

To make systems run more efficiently

The demand for heat in a glasshouse changes seamlessly over time, from zero up to a maximum requirement. However, the output of most heat generators, such as boilers, is ‘staged’ in what might be a small number of discrete steps.

Therefore, to meet glasshouse heat demand accurately, a heat generator may have to switch on and off (or ‘cycle’) constantly. In so doing, it operates less efficiently; the constant heating and cooling of the core of the device wastes energy. Using the heat store as a buffer allows the heat generator to operate for longer sustained periods and so avoids rapid cycling and improves efficiency.

It is the heat delivery from the store that copes with the seamless changing demand from the glasshouse, not the heat generator.

With the introduction of heat sources like biomass boilers, the ability to buffer heat output is especially important, as this type of boiler does not lend itself to even infrequent cycling. A heat store can also act as a safety mechanism; when heat demand stops, but the boiler is still hot, the heat store will continue to absorb heat from the boiler, preventing it from overheating.

To make heat generators smaller

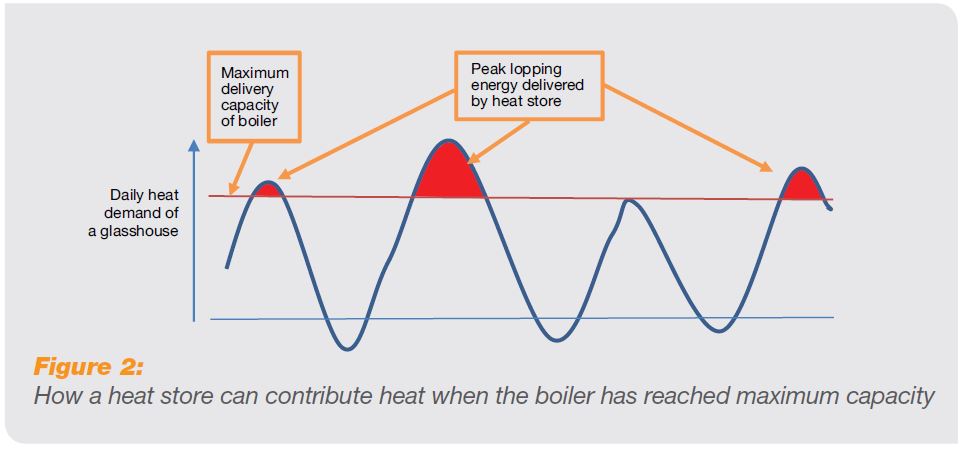

A heat generator which has no heat store has to be sized to meet the peak heating demand of the glasshouse. With a heat store, however, it is possible to use the store to ‘peak-lop’ heating demand and so size the boiler according to sustained demand (Figure 31).

Figure 2. How a heat store can contribute heat when the boiler has reached maximum capacity

To allow multiple heat generators to coordinate effectively

A well-operated heat store can be regarded as the primary source of heat for a glasshouse, with each heat generator used to replenish the hot water in the store rather than to heat the glasshouse directly. If configured in this way, each heat generator can be operated at its most efficient point and most appropriate time without reference to the heat demand of the glasshouse. For instance, CHP can be operated when electricity or CO2 is required, or biomass boilers fired over long periods even during periods of cyclic heat demand without compromising the efficient operation.

To give heating backup

No one should install a heat store for backup purposes only, but it can be useful if things go wrong. Heat stores can be invaluable in meeting short-term heat demand when primary heating generators fail. They also allow the possibility of introducing alternative heat sources in a seamless way. For example, a new boiler or heating device need only be connected to the heat store, leaving the primary heating circuits feeding the glasshouse undisturbed. The store forms an interface, or buffer, between the heat-producing equipment and the glasshouse heating system.

Useful links

Learn what is the best medium to store heat

Visit our GrowSave pages to read more about energy-related topics

Got a question. Ask a member of the team:

Topics:

Sectors:

Tags: